6.0 Powerstroke Turbo Not Working

If Your Powerstroke Turbo Is Not Working, Let Me Help You Diagnose the Problem. Is Your Turbo Blowing Oil Past the Seals Causing the Engine Exhaust to Burn Oil Out the Tailpipe, If so You will see White Smoke With a Blue Tint. The Exhaust Will Smell like Burning OIl and Not like Diesel Fuel. Your Blue White Smoke Condition Can Go Away When The Engine Warms Up. If Your Turbo Is Leaking Oil, then it Needs a Rebuild and Needs to Be Replaced.

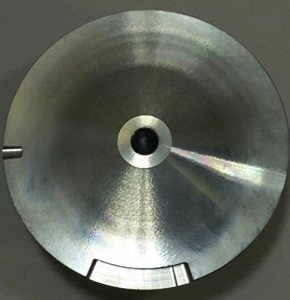

If The Turbo Takes a long time to Build Boost, But Makes Great Power in Higher RPM, then the VGT System Needs to Be Cleaned. It is Necessary To Blast the turbine housing, Bearing Housing, and VGT Parts To Fix This Problem. The Reason Why the VGT System Sticks, is because The Bearing Housing Rusts and Makes the Unison Ring Stick To The Bearing Housing Which Will Not Allow the Turbo to Build Boost Effiecently. The Vanes can be Stuck In Open Position for High RPM or Closed Postion for Low RPM. If Stuck In Open Position the Turbo will Take a Long Time To Spool Up, But the Turbo will Perform Great At Higher RPM. If the VGT Is Stuck In Closed Position, then the Turbo Will Spool Up Fast But it will Run Out of Power at Higher RPM. If You Have This Problem, then the VGT System Needs a Good Cleaning, I recommend Sand Blasting in a Professional Media Blasting Cabinent with a Vacuum Filtration System, Then Painting to Prevent Rust.

You Have 2 Options, You Can Rebuild Your Turbo Or Buy a New 6.0 Powerstroke Turbo. Here “6.0 Powerstroke Turbo Rebuild” You can Learn How to Rebuild The Powerstroke 6.0 Turbo. And Here You can Buy a New 6.0 Powerstroke Turbo Replacement.