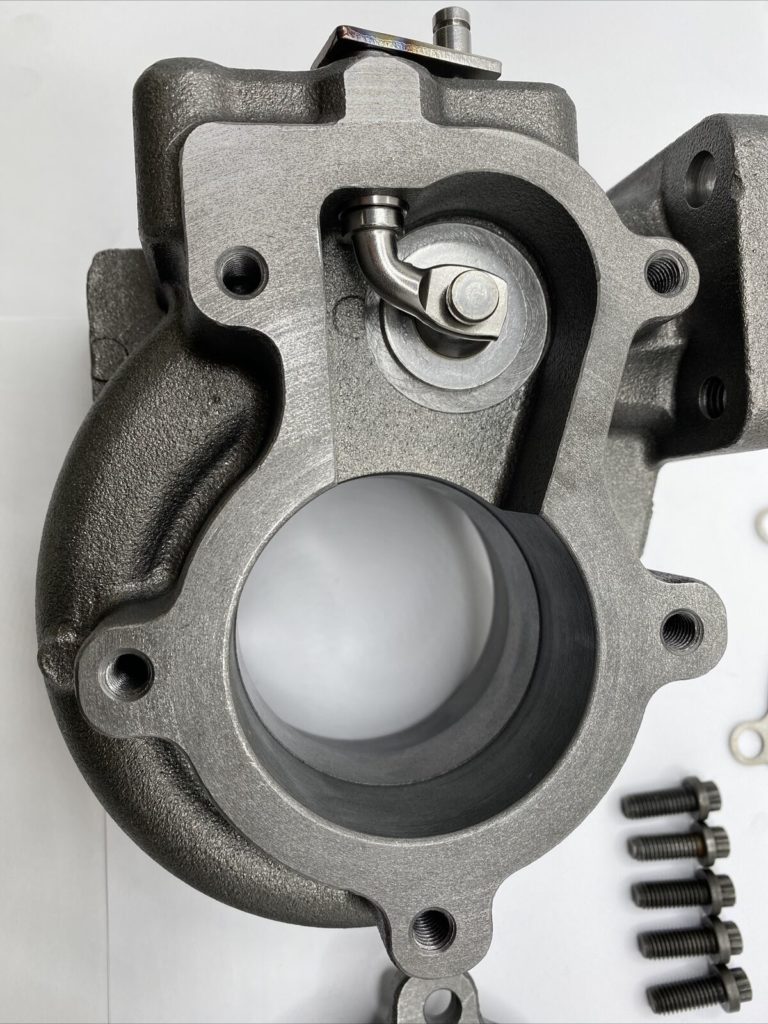

HX35 64mm x 76mm turbine Wheel and exhaust housing upgrade.

Please Read Carefully: This Housing is made to directly fit 1998 -2002 24v turbochargers as a upgrade. To work on other models modification is need as listed below:

Modifications Required to fit 12v model turbos: (there are 2 versions of 12v Engines)

-To fit 12v turbos normally using horizontally mounted actuators, the threaded holes must be drill on the t3 flange for the manifold studs to go through the turbine housing. (thats it!)

-To fit 12v turbos normally using vertically mounted actuators, the threaded holes must be drill on the t3 flange for the manifold studs to go through the turbine housing, and the wastegate arm must be repositioned to operated vertically rather than horizontally. The arm must be cut off and rewelded. (Some 12v models cannot use the horizontal actuators because they interfere with the oil drain which won’t allow the turbo to bolt on.

Explanation of the fitment Modification:

This is a custom made housing, the t3 divided flange is threaded for 2 studs for the purpose of bolting onto an HX35 Dodge ram 1998.5 – 2002 24v exhaust manifold. If you want to use this with a 1989 -1998 12v manifold, the threaded holes will have to be drilled out larger on this turbine housing for the 12v manifold studs to allow the turbine housing to bolt on. (The 12v Exhaust manifolds have 4 threaded holes for studs on the manifold). In addition, this turbine housing is designed to be used with wastegate mounted to a 24v 1998-2002 compressor housing or you can use a 12v horizontal mounting wastegate actuator + mounting hardware, but only on 24v engines or 12v engines where the horizontal actuator wont interfere with the oil drain.

This turbine housing’s wastegate arm can be repositioned (cut off rewelded) to work with vertically mounted wastegate actuators, but not every 12 valve engine will allow a horizontal actuator to bolt on because the oil drain on some 12 valve engines will be in the way not allowing the horizontal actuator and turbo to bolt on. In summary some 12v engines can use a horizontal mounting wastegate actuator & Turbine housing and some cannot, but the turbine housing’s wastegate arm’s position can be changed to work with a vertical or horizontal mounting wastegate actuator, but you must have the matching wastegate actuator and mounting hardware. At the time of this writing, i only have the vertical mounting wastegate + hardware.

Details of the listed items:

Upgrade for the 24v 5.9.

Includes:

- Fits 1998 – 2002 24v cummins factory hx35 turbo as upgrade

- Hx40 64mm x 76mm turbine shaft

- Hx35 turbine housing machined to hx40 64mm x 76mm turbine

- 5 bolts

- 5 bolt flanged machined to the 64mm x 76mm turbine

- 5 bolt downpipe gasket

- The Wastegate orientation is mounted on the compressor housing.

- Wastegate not included.

- Recommended to use this turbine housing with HX40 60 x 86 or 62.45 x 86 billet compressor wheel

- Condition is New