To get the most life out of your turbocharger it is very important to understand how turbochargers fail. The most common reason for failure is the seals leaking in the turbocharger because of wear. Shutting your engine off immediately after hauling heavy loads in your truck or doing hard pulls in your car, causes the oil on the turbine to dry up. The next time your start the vehicle the turbocharger will experience a dry start and this is what causes the wear. If you allow your engine to idle after putting your vehicle under extreme loads, the engine oil will circulate and take away the heat in the engine and turbo charger. The recommended idle time is 1 to 5 minutes depending on how hard you push your car or trucTo get the most life out of your turbocharger it is very important to understand how turbochargers fail. The most common reason for failure is the seals leaking in the turbocharger because of wear. Shutting your engine off immediately after hauling heavy loads in your truck or doing hard pulls in your car, causes the oil on the turbine to dry up. The next time your start the vehicle the turbocharger will experience a dry start and this is what causes the wear. If you allow your engine to idle after putting your vehicle under extreme loads, the engine oil will circulate and take away the heat in the engine and turbo charger. The recommended idle time is 1 to 5 minutes depending on how hard you push your car or truck.

Lack of Lubrication

The next common cause of failure of your turbo is running to thin of oil. The thicker the oil the better the protection in higher heat conditions. The thinner oil is for extreme cold conditions. The oil weight for your engine is just as important for your turbo, and you should go by what the manufacture recommends. For race car applications, its important to go with racing oil. I have one customer that lives in the below 0°F temperature, and he would put 5w 30 motor oil in it in the winter, which is fine for those temperatures, but when summer came around every year, his turbo would fail. The manufacture of his turbo recommends 10w 30 year round.

How does oil contamination damage turbos?

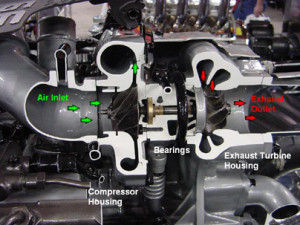

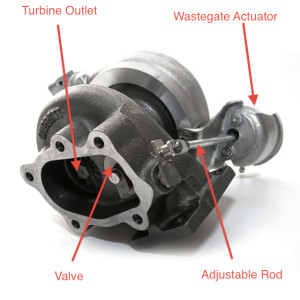

Oil contamination is another common cause of failure of turbochargers. Oil contamination can be carbon, sludge, metal flake, or dirt which gets in the turbocharger and clogs up the thrust bearing and causes in and out play, or locks up a bearing and shaft and causes the shaft to break. The most common problem of oil contamination is metal flake and carbon clogging up the thrust bearing of a turbo. I have also seen parts of stripped threads inside a thrust bearing. To help prevent oil contamination you can run the oil pressure from the oil filter housing directly to the turbocharger. Most contaminates in the oil are found in the cylinder head, by taking oil straight from the oil filter you are taking the cleanest oil available and bypassing the cylinder head. When a turbo blows oil it puts your engine and its components at high risk for failure, because the oil pressure become lower. Also when the oil level gets to so low that the oil pressure becomes non-existant.

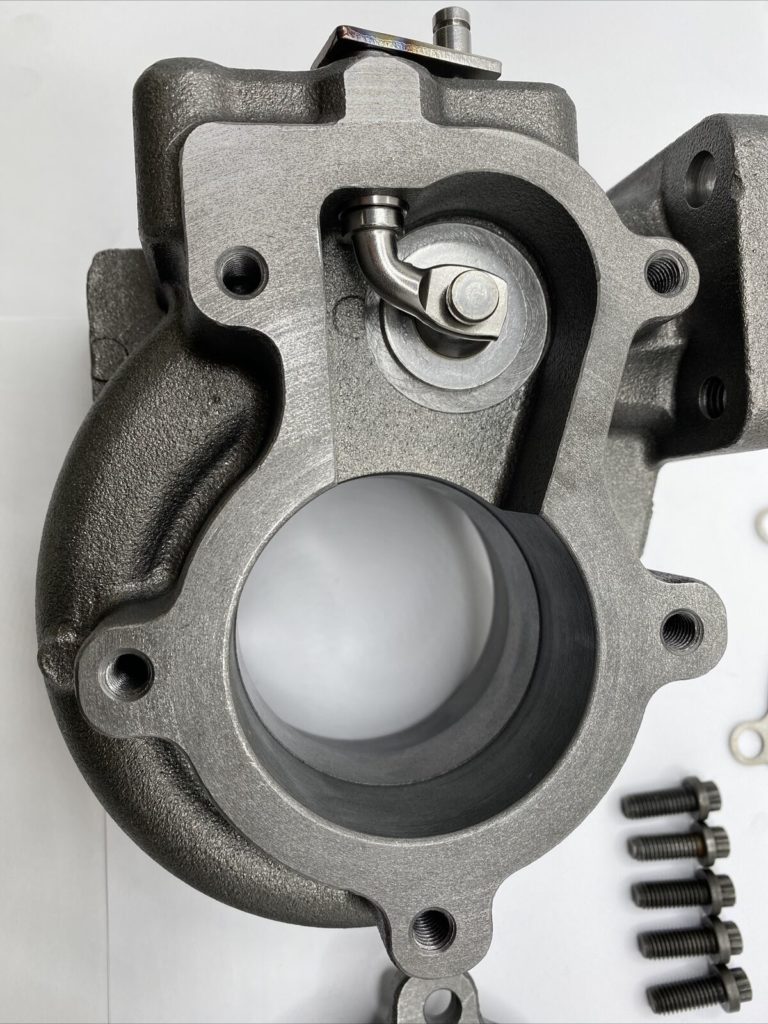

As turbochargers can operate at over 240,000 rpm and temperatures of 950°C, turbo bearings are under great stress. The turbine shaft and bearings rotate in a thin film of oil. Consequently any fault with the oil supply to the turbo means its bearings are likely to fail before the engine’s main bearings. Running a turbo without oil for five seconds is more harmful as a motor running without oil for five minutes. Since the turbo spins over 39 times faster than an engine, you will see a turbo fail 39 times soon than the engine. When a turbo blows oil it puts your engine and its components at high risk for failure, because the oil pressure become lower. Also when the oil level gets to so low that the oil pressure becomes non-existant. When a turbo is leaking oil, it also is causing a drop in oil pressure to the rest of the engine. This concept can be compared to a water hose being sprayed, if you poke a hole in the hose, the water will still be sprayed out of the hose but the pressure is much lower.

. While it is important to check the engine oil pressure meets the manufacturer’s specifications, it is even more critical that the oil feed lines to the turbo are clean and clear, so you are certain they can supply uncontaminated oil, at the correct pressure. Contaminated or dirty oil will scratch or score the bearings, leading to rapid wear and ultimately, turbocharger failure. 95% of turbo failures are because of problems with oil starvation, oil contamination or foreign object damage.

What causes contaminated oil?

A blocked, damaged oil filter, carbon build-up in the engine, engine parts transfer over from a blown engine, and accidental contamination of new oil during servicing.such as a cylinder head are all often causes of repeated oil contamination causing even new turbo chargers to blow oil immediately after install. This can rapidly contaminate even new oil. On some vehicles, the oil bypasses the oil filter above 4500 rpm to provide better oil flow to the engine. Another type of oil contamination is gasoline or coolant. Having gasoline in the oil is often caused from worn spark plugs not burning the fuel off or from acids that build up in the oil from use causing premature wear from not changing the oil on time. Coolant in your engine oil is just as damaging as pouring water in your engine oil and expecting the water to lubricate the engine parts. The coolant in the engine can cause the engine or turbo charger to hydro-lock.

Preventing turbo failure

• Always use fresh oil, the correct oil weight, and new oil filters as recommended by the engine manufacturer when installing a new turbo. We do not recommend using an inline filter in the oil feed line of the turbo charger because it can clog and cause problems, the best way is to run your oil feed line straight a location where oil has just pass through the oil filter. Often if there is something wrong with the motor’s oil pressure, regardless if the turbo that you install is good, it will blow oil. Clean or replace oil feed and return lines to eliminate any carbon deposits or sludge that can enter the turbo or restrict the oil flow to the bearings. Before installing a new turbo, find out what caused the first turbo to fail or you risk the replacement turbo failing too.

Turbo Lab supplies remanufactured replacement turbochargers, made by the original manufacturers to the highest quality standards. Though we confidently guarantee them, our standard warranty does not cover turbocharger failure caused by oil contamination or lack of oil.