Subaru WRX Turbo Upgrade

This is Our Subaru Wrx turbo Upgrade option for the Factory Turbochager, you must Provide a Core Turbo For This Service. We do the TDO4HL Upgrade For $550 (50x62x65 bcw and 45 52 9 Blade TW).

- TDO4 Upgrade Option 50x 62 x 65 Billet Compressor Wheel

- TDO4HL 45 x 50 9 Blade

- TDO4 TDO4H TDO4L TDO4HL Upgraded Turbo Rebuild Kit

Here are Larger Turbo Upgrade Options That We Build Brand New.

Subaru STI, Legacy GT, WRX Turbo Upgrade Options

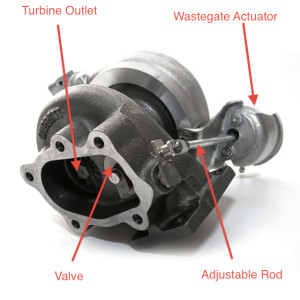

We Also Build Larger Turbos 16g, 20g, and Larger For $750 without Wastegate or set up for External Wastegate and $850 with an Internal Wastegate Actuator. (You do not have to provide a core turbo for the 20g turbos or larger, we build new units.)

- 16g 48.3mm x 68mm compressor wheel / tdo5h 12 or 9 Blade Turbine Wheel 375-400hp

- 18g 50 x 68mm compressor wheel / tdo5h 12 or 9 Blade Turbine Wheel 400-425hp

- 20g 52.6mm x 68mm / tdo5h 12 or 9 Blade Turbine Wheel / TDO6SL2/TDO6/TDO6H 400-450hp

TDO6, TDO6sl2, TDO6H Series ($800 without Wastegate Actuator $850 With)

- 56 x 76 x 79 7+7 Blade Billet Compressor Wheel /TDO6, TDO6SL2, or TDO6 500hp

- 58 x76 x 80 11 blade GTX3076r Compressor Wheel / TDO6H Turbine 550hp+

- 60.27 x 82 x 83 7+7 Blade Billet Compressor Wheel / TDO6H 9 blade 600hp+

- 60.5 x 78 x 83 5+5, 6+6, or 11 blade 25g Billet Compressor Wheel / TDO6H 9 blade 600hp+

Turbine Wheel Upgrade Options:

- TDO5H 49mm x 56mm 12 or 9 blade

- TDO6SL2 54mm x 61mm 11 or 9 blade

- TDO6 55mm x 65mm 12 blade

- TDO6H 58.8 x 67.2 11, 9 blade unclipped, 9 blade clipped (I recommend 9 blade clipped or unclipped because it’s 100 grams lighter than the 11 blade)

Contact Us For a Turbo Build: turbolabamerica@gmail.com