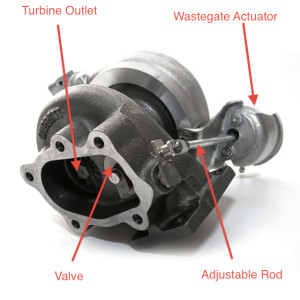

Often when building custom turbos people will want to make a good deal of power and still have decent spool time. The best way to accomplish great spool up on a higher flowing turbo is to put a smaller turbine housing on it. A good example is taking a holset hx40 and replacing the factory .89 a/r housing and replacing it with a bep .55 a/r bep housing for a dsm. The hx40 with the bep housing will be limited to 550-600 hp range instead of the 700 hp mark that people have made with the .89 a/r, but the spool time will increase which makes the turbo more streetable. Another good example is having us machine a garrett t3 .63 a/r turbine housing to fit an hx35 or hx40. This will limit what this turbo is capable of flowing, but it will bring down the capable flow rates of the turbo down to size with a smaller engine to help spool time and over all efficiency. A good example is if you pair an hx35 with a 16 cm^2 turbine housing with a 2.0 liter 4 cylinder motor. If the car can ever spool that turbo up it will make huge amounts of power, but it wont start seeing boost until around 5,500 rpm in 3rd gear. If you had us machine a .63 a/r turbine housing for the same hx35, then the spool time will be moved to the 3,000-4000 rpm range depending on your boost level and it will still be capable of 450-500 hp. The turbine housing choice that is best for your application depends on the displacement and number of cylinders of the engine that you are turbo charging. Another deciding factor is what kind of power you are looking to make and drivability. When choosing a turbine housing you are sacrificing capable horsepower for spool time.

Often people will ask: should I go t4 or should I go t3 for my exhaust housing? This best way to answer this is by asking your self what kind of HP you want to make, and what kind of spool time you want to see. Also keep in mind the motor that you are using too. If its a 2.0 and your trying to make 450 awhp and you want to have decent spool time, I would recommend that you choose a t3 .63 a/r turbine housing or close. If you are turbocharging a 5.0 v8, the motor is naturally flowing 5 liters of air, so it makes sense that you need to used a larger turbine turbine housing in the t4 format to avoid choking the flow of the engine at higher rpm. If you want decent spool time you want to put a turbo on the car that has flow rates close to the engine. If you use a turbo that flow less than the motor at 6500 rpm, then at 6500 rpm at wide open throttle you will feel the car stop pulling because the motor is having a hard time flowing more air because turbo turbo is limiting the flow. The fix for this would be to upgrade the turbine housing or the turbine wheel and compressor wheel. A good example is an evo 9 20g that we built that made 493 awhp, but the car choked at 6500. We never upgraded the turbine shaft of this turbo so the measurement were 52mm x 68mm for the compressor wheel and 49mm x 55.6mm for the turbine wheel. The reason the car was capable of 493whp, is because the turbine housing is twin scroll and 10.5 cm from the factory. If we wanted to help the car pull harder in the higher rpm range, we upgrade the turbine shaft to a tdo6h4R (58mm x 67mm) or tdo6sl2R turbine (54mm x 61mm). Though both turbines would help the turbo pull to redline, the tdo6sl2 turbine would be the best for spool time and the tdo6h4R turbine would be better for more power. The main reason why we upgrade the turbine wheels in most turbos that we build is because it is very limited for the turbine housing sizes for factory cars. In most cases there are no upgraded turbine housings, so we upgrade the turbine shafts as an alternative, which works better if your trying to retain some of your spool time.

There is not a direct conversion for an A/R to cm^2 estimate but this chart works well for an estimate.

A/R to cm^2 estimate

6 cm2 = 0.41 A/R

7 cm2 = 0.49 A/R

8 cm2 = 0.57 A/R

9 cm2 = 0.65 A/R

10 cm2 = 0.73 A/R

11 cm2 = 0.81 A/R

12 cm2 = 0.89 A/R

14 cm2 = 0.97 A/R

15 cm2 = 1.05 A/R

16 cm2 = 1.13 A/R

17 cm2 = 1.29 A/R

19 cm2 = 1.37 A/R