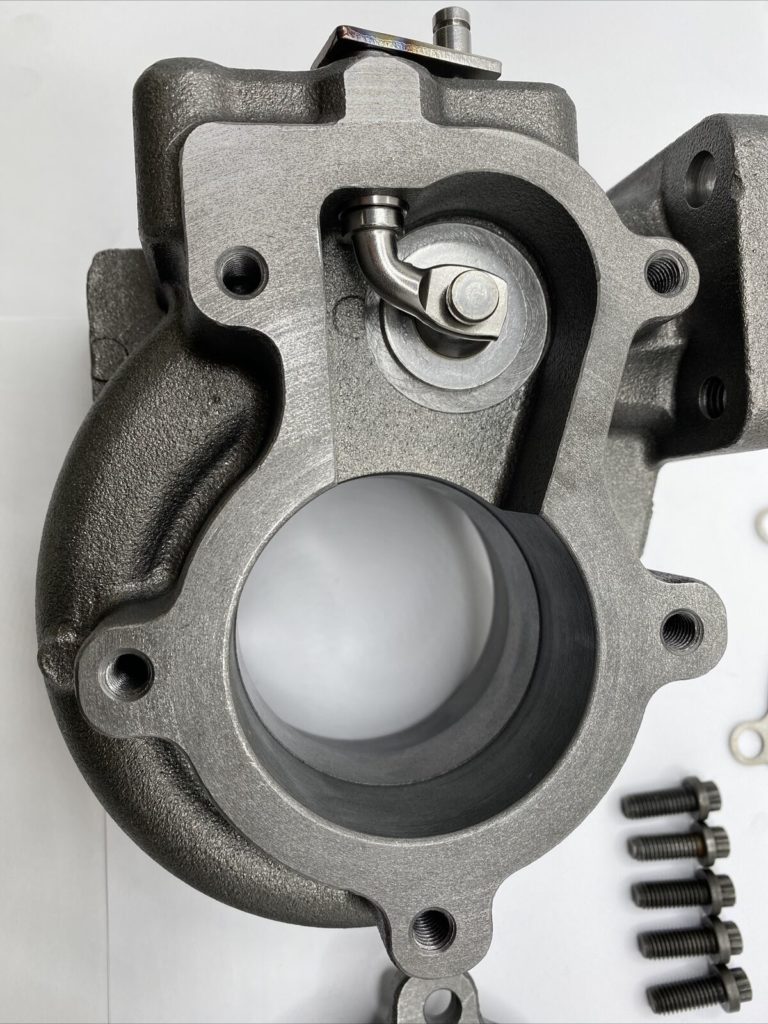

HX35 64mm x 76mm turbine Wheel and exhaust housing upgrade.

Please Read Carefully: This Housing is made to directly fit 1989 1997 24v turbochargers as a upgrade. To work on other models modification is need as listed below:

1989-1997, have some variations of the factory turbo charger, this turbine housing and wheel work as an upgrade to the H1C and HX35, even though there are different version, in which some did not include wastegate actuators, this housing is still a direct fit on the factory turbo chargers in combination of using the turbine wheel included. This kit is intended to be used with a compressor upgrade 60mm, 62.45mm, or 67mm.

The turbine housing in this listing has 4 drilled through holes at the t3 flange, because the 12v engines use 4 studs threaded into the manifold. The 24v cummins (98- 02) has 2 threaded holes on the turbine housing and 2 threaded holes on the manifold to use studs. If this housing is used on a 24v cummins, 2 bolts and nuts will need to be used to bolt on the turbine housing because the exhaust manifold and turbine housing is not threaded for studs and the manifold is only threaded for 2 studs. If you are using this kit on a 24v you will not need to use the factory 24v wastegate actuator and mount on the compressor housing.

–If you are using this turbine housing on a 12v turbo with a horizontal mounting wastegate actuator, no actuator, or vertical wastegate actuator, this is a direct fit.

Modifications Required to fit 12v model turbos: (there are 2 versions of 12v Engines)

-To fit 12v turbos normally using horizontally mounted actuators, the threaded holes must be drill on the t3 flange for the manifold studs to go through the turbine housing. (thats it!)

–Some 12v models cannot use the horizontal actuators because they interfere with the oil drain which won’t allow the turbo to bolt on. However, the vertical mounting wastegate actuator is universal, there for this turbine housing upgrade is a universal fit for both model 12v engines.

Details of the listed items:

Upgrade for the 12v & 24v 5.9 cummins

Includes:

- Fits 1989 – 2002 12v & 24v cummins factory HX35 turbo as upgrade

- Direct fit for 1989 – 1997 12 valve turbo chargers / engines

- 2 bolt and nuts are needed to fit 1998 – 2002 24v because no threaded holes on t3 flange (no threads for studs)

- HX40 67mm x 76mm turbine shaft

- HX35 turbine housing machined to HX40 67mm x 76mm turbine

- 5 bolts

- 5 bolt flanged machined to the 67mm x 76mm turbine

- 5 bolt downpipe gasket

- The Wastegate orientation is mounted on the compressor housing.

- Wastegate not included.

- Recommended to use this turbine housing with HX40 60 x 86 or 62.45 x 86 billet compressor wheel

- Condition is New