Below I will introduce you to our available billet compressor wheel options 60mm 62.45mm and 67mm. But first here are the factory specs.

2003 – 2004 Dodge ram 2500 & 3500 factory turbo specs: 54mm x 78mm or 56mm x 78mm (7+7 blade) compressor wheel, and 58 x 65mm turbine wheel.

2004 – 2007 Dodge ram 2500 & 3500 factory turbo specs: 60mm x 86mm (hx40 7+7 blade compressor wheel)

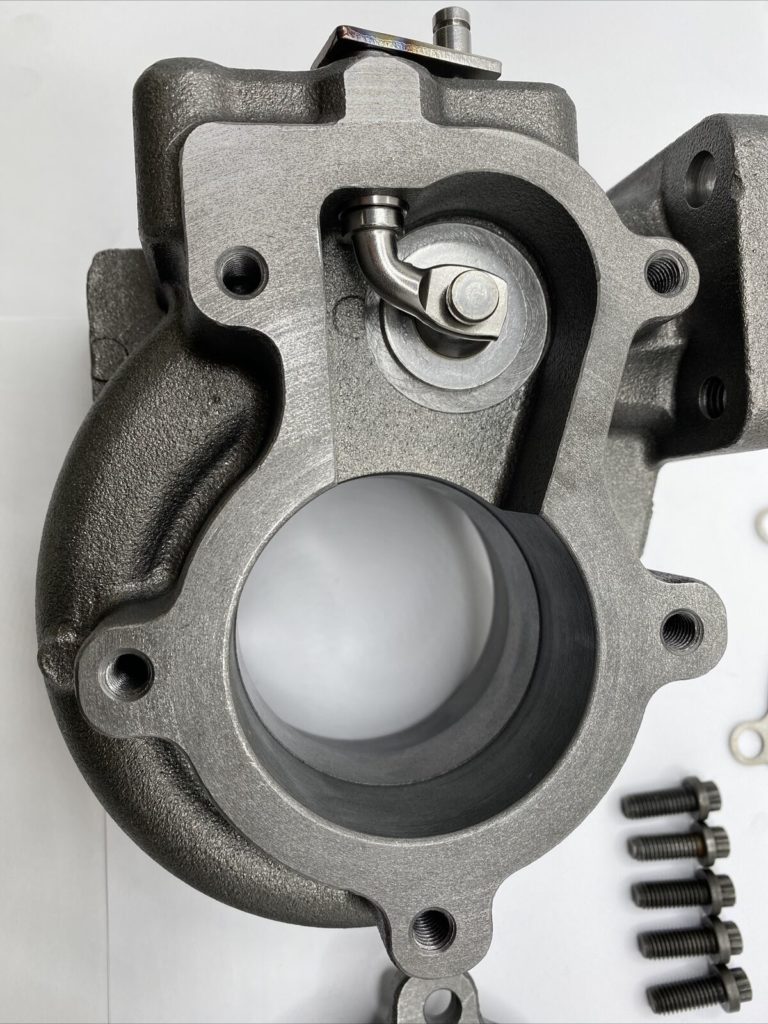

Our upgraded compressor wheel and housings are for the 2004.5 -2007 Dodge ram with the 5.9 cummins, if you want to use our compressor housing and wheel on the 2003 – 2004 model, the bearing housing will have to be machined to fit the larger exducer of the compressor wheel (factory is 78mm and the upgrades range from 86 to 89mm, the bearing housing’s compressor wheel pocket has to be machined 1.2mm larger than the compressor wheel) or you can buy our HE351CW bearing housing from our Ebay listing which is machined for our 67mm compressor wheel and compressor housing oring. . Also the boost control solenoid will need to be deleted to work on the 2003 – 2004 model turbos. There are block off plates available on Ebay as well.

Here are our compressor wheel and housing upgrade options for the 2005 – 2007 5.9 Cummins turbo models: 62.45mm x 86mm 650hp option (click to buy from our Ebay listing) and 67mm x 89mm x 95mm 725hp option (click to buy from our Ebay listing). It is recommended to use our turbine housing and turbine wheel in combination of the compressor wheel upgrade, to increase hp and lower EGTs and drive pressure. We also have built turbos available. We also machine our bearing housings for O-rings to insure that the compressor housing will seal properly, the turbo original does not have a seal for the compressor housing.