Boost creep– Boost creep is caused when a free flowing exhaust system is put on a turbo charged car. When revving out to higher rpms your boost pressure(psi) will rise as your rpms of the motor rise. This happens because the waste gate passage can not flow enough air to by pass the turbo to control the boost efficiently. The reason why this happens when you change out the exhaust to a free flowing exhaust is because you the smaller exhaust provided back pressure which caused resistance to flow air passed the turbine wheel.

Boost creep– Boost creep is caused when a free flowing exhaust system is put on a turbo charged car. When revving out to higher rpms your boost pressure(psi) will rise as your rpms of the motor rise. This happens because the waste gate passage can not flow enough air to by pass the turbo to control the boost efficiently. The reason why this happens when you change out the exhaust to a free flowing exhaust is because you the smaller exhaust provided back pressure which caused resistance to flow air passed the turbine wheel.

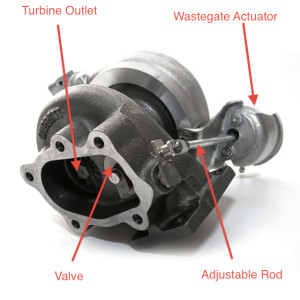

How to fix this: You can port the waste gate flapper area and add a bigger flapper valve to help prevent boost creep, but the best way is to go external waste gate and select the appropriate waste gate spring for the boost level that you plan to run. We find that it works best that the wastegate spring base pressure should be half or more than the boost pressure that you plan to run. So if you are running 30 psi, then you should have a 15 psi wastegate actuator. The problems with porting the flapper hole and adding a bigger flapper is that it makes it harder to run higher boost levels. Dsm guys will see that there boost level will spike to their set boost level (lets say 20 psi), then when their rpms increase the flapper valve will have a hard time closing, because of the increased surface area of the bigger flapper valve in combination with the waste gate base spring pressure being to low, which makes the flapper struggle to shut to control the massive amount of air pressure that is coming through the turbine housing. When the valve is having a hard time closing it is releasing more pressure out of the turbine housing than it is supposed to their for even though your boost level is set to 20 psi it will fall off to 16 psi and hold a lower boost level to redline. The best way to go is to go external waste gate.